Roller line

Carrying a wide range of product types, less restrictions, blocker use, can achieve the continuous product, beat operation and build-up function, the use of top-up translation device, can achieve offline repair or detection of the product without affecting the operation of the entire assembly line.

Product description

Parameter configuration

Carrying a wide range of product types, less restrictions, blocker use, can achieve the continuous product, beat operation and build-up function, the use of top-up translation device, can achieve offline repair or detection of the product without affecting the operation of the entire assembly line.

Product form

Related Products

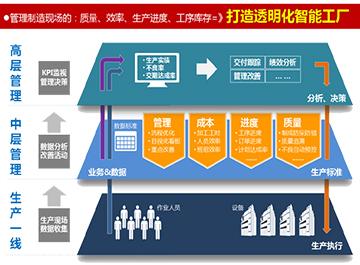

MES (Manufacturing Execution System, Manufacturing Fulfillment System) is a management and scheduling exercise between the planning layer and the field operation control layer. MES enhances the competitiveness of manufacturing by controlling all plant resources, including materials, equipment,…

Continuous lifter is a link equipment of plane conveyor system between different floors, which mainly acts on the transportation of goods between multiple floors, and is often used in conjunction with other conveyors. Suitable for the transport of geometric objects (e.g. trays, cartons, enclosures…

The workplane can be transmitted freely, the use of blocker positioning to make the workpiece move freely or stop, the workpiece at both ends can be automatically raised, cross-shift transition. Rotating (90 degrees, 180 degrees) can also be installed on or next to wire bodies. ), special aircraft…

Submitted successfully

We will contact you as soon as possible

Close