MES Intelligent Management System

(1) Improve the formulation and adjustment of production plan: improve the efficiency and accuracy of production plan development through MES production plan management module.

(2) Speed up the feedback speed of the implementation of the production plan of the enterprise: with the production plan at the process level, in the production and processing process of the product, the reaction speed of processing information and processing status will be much higher, after the completion of a processing process of the product, it can be reflected in the MES system, can be real-time statistics, so that the actual production situation of the enterprise can be accurately reflected in the first time.

(3) Improve equipment management: through the MES equipment management module, all the equipment of the enterprise can be established a clear online electronic account. Record the location of the equipment, the condition of the equipment, the regular inspection of the equipment, overhaul, etc.

(4) Product life cycle tracking, improve the quality control in the production process: through the MES system quality control module, for each processed product to establish a separate quality tracking record, all the product-related quality control data in the MES system centralized storage, through the query can be viewed at any time.

(5) Real-time data monitoring, eliminate information silos in enterprises, and realize information sharing within enterprises: through MES this platform, all the data related to production in the enterprise is linked together, eliminating the information silos between the various sub-systems. Make product design, process design, manufacturing, quality control and other aspects related to the production process into a whole.

(6) Improved real-time data reporting capabilities: through the MES system of the common statistical analysis module and specifically tailored to the actual needs of users of statistical analysis, can speed up the enterprise real-time production report summary time and improve data accuracy.

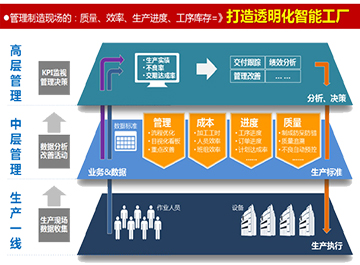

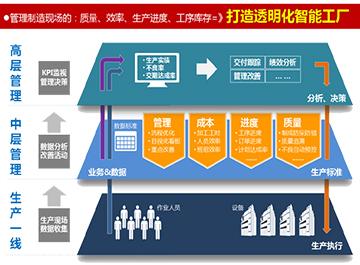

MES (Manufacturing Execution System, Manufacturing Fulfillment System) is a management and scheduling exercise between the planning layer and the field operation control layer. MES enhances the competitiveness of manufacturing by controlling all plant resources, including materials, equipment, personnel, process instructions, and facilities, and provides a way to integrate quality control, document management, and production scheduling capabilities on a unified platform.

Related Products

Submitted successfully

We will contact you as soon as possible